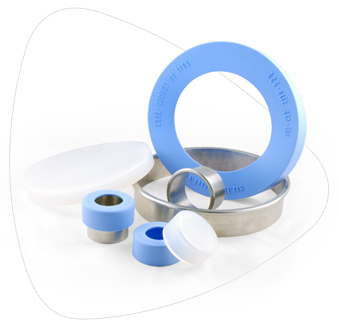

Silicone Dust Caps

Application of Silicone Dust Caps in

'Powder Containment'

Powder containment is a major issue in the process industries, the Uni-Cap has been designed to help manufacturers comply with the stringent standards required.

The Uni-Cap is hygienically moulded in one piece from FDA compliant pure silicone rubber, offering a durable easy-clean solution to containment of powder during transfer.

The Uni-Cap, Dust Cap Seal has a high-quality finish and is ideal for use where a fast temporary dust-proof connection is required for powder transfer.

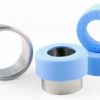

Standard material is translucent silicone, but special colours can be supplied subject to quantity and colour request. A corresponding range of stainless steel support rings is also available, manufactured from 316L stainless steel; various surface finishes can be provided.

- Profile

Manufactured using FDA compliant silicone, The Uni-Cap, Dust Cap Seal, is ideal for use in pharmaceutical, chemical and cosmetic or food applications.

The dust caps help to contain powder and create a safer working environment, ensuring operators are fully protected during the transfer stage of powder processing.

Whereas some types of round profile flange rings supplied with conventional dust caps have an unhygienic rolled lip, the Uni-Cap is designed to fit standard Tri-Clover ferrules, which eliminates this problem.By integrating the cap itself with stainless steel support rings, the Uni-Cap system provides a very simple and cost effective way of creating a ‘closed-system’.

In addition, the hygienic one-piece moulding can be easily cut for spigot connections.

After transfer of materials, the Tri-Cover entry can be capped with a standard stainless steel 'blank-cap' or re-connected for further processing operations.

The Uni-Cap is fully washable and can withstand temperatures of up to 200C making it suitable for hand-washing, washing machine or autoclave.

- Features

•Dust tight connection

•FDA compliant silicone

•Excellent GMP design

•Durable and easy-clean

•No tools required

•Hygienic stainless steel support rings

•Fast and reliable assembly- Technical Specifications

-

•Dust Cap Material of Construction: FDA compliant silicone (FDA CFR 177.2600)

•Support Ring Material of Construction: 316L stainless steelCaps

Nominal Diameter

Maximum Inlet Spigot Dia.

Height

Part No.

60 mm

50 mm

33 mm

736564

200 mm

150 mm

40 mm

736570

250 mm

200 mm

36 mm

736565

315 mm

265 mm

32 mm

736567

400 mm

350 mm

32 mm

736572

Support Rings

Nominal Diameter

Maximum Inlet Spigot Dia.

Height

Part No.

57mm

50 mm

50 mm

735688

200 mm

204 mm

50 mm

735689

246 mm

250 mm

50 mm

735690

314 mm

318 mm

50 mm

735691

400 mm

404 mm

50 mm

735692

- Typical Applications

-

•Dust free transfer from IBC to IBC

•Milling into an IBC

•Vacuum conveying into an IBC

•Used on underside of IBC outlet valves during transportation to contain powders - Gallery

Download Brochure:

Unknown

Unknown Unknown

Unknown Mozilla

Mozilla