Vacuum Conveyors

Uni-Vac Systems

Welcome to our vacuum conveying section.

This area is designed to help you find out everything you need to know about vacuum transfer of material in general, and Hanningfield’s 'Uni-Vac' vacuum conveying systems in particular.

Whether you are seeking to understand the principle of conveying itself, want to ask a question or are looking for a conveyor, our aim is to solve your problem.

With many years worth of knowledge, Hanningfield are experts in the design, manufacture and maintenance of vacuum transfer solutions and would be please to share this knowledge to help improve your process.

Please select your area of interest below:

- What is Vacuum Conveying?

-

Vacuum transfer systems are an excellent method of moving powder, granules, pellets and other materials from ‘Point A’ to ‘Point B’.

The systems use a vacuum to carry the material through the pipework, allowin material to be transferred in a gentle, yet rapid manner. This allows up to 4,000 kgs/h to be transported, without significant disturbance to the characteristics of the product.

Vacuum conveying is a method of transferring material in a fully contained and hygienic way. Material, such as powder, pellets or granules is loaded into the conveyor and is transported to an end-destination via pipe work. Vacuum technology provides a cost effective flexible solution to the safe conveying of bulk materials across a broad spectrum of process industries.

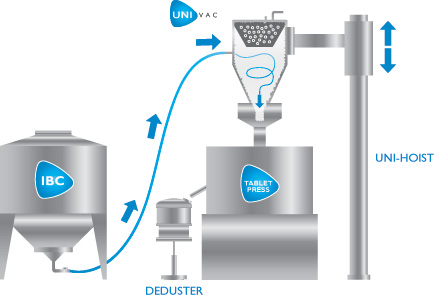

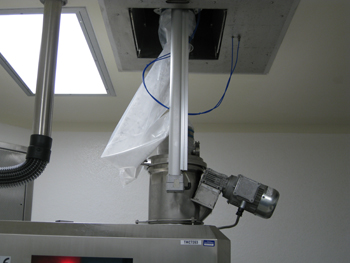

Example Uni-Vac Application: Feeding a Tablet Press

Ideally suited to powders, granules and similar materials, vacuum conveying ensures a ‘dust-tight’ product transfer is achieved. The closed-system approach for material transfer ensures that no dust escapes to atmosphere and no contamination from outside can enter the system. This important feature of the vacuum conveying process ensures system operators are well protected from hazardous products.For example, powder can be sucked directly from an IBC, into the conveyor, and then transferred from the conveyor to the required destination, such as a tablet press, cone mill or filling machine. In this regard the conveyor acts as a temporary storage container, holding the process material until it is ready to be dumped or loaded into the process machine. This allows the process to be carefully controlled, as the throughput can be moderated in accordance with each customer’s individual requirements.

The diagram here shows a basic example of how vacuum conveying from an IBC into a tablet press works.

- How Does Vacuum Conveying Work?

-

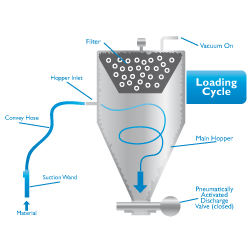

Vacuum conveying consists of two cycles; the loading cycle and the unloading (discharge) cycle. Each works as follows:

Vacuum conveying consists of two cycles; the loading cycle and the unloading (discharge) cycle. Each works as follows:The Loading Cycle:

Material is sucked into the vacuum hopper by using a hand held vacuum wand or feed-bin arrangement. During the loading or ‘convey cycle’ vacuum is drawn on the vacuum hopper lid through a filter, thus drawing the material to be conveyed into the vacuum hopper chamber. Vacuum is present throughout the loading cycle and interrupted only during the unloading cycle. The outlet or ‘discharge-valve’ remains closed during the loading phase.

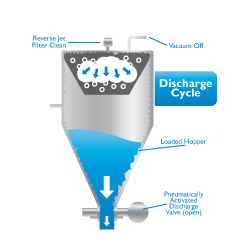

The Unloading (Discharge) Cycle:

Once the hopper is full (controlled by timer) vacuum is relieved and the discharge valve at the base of the vacuum hopper opens. Material then falls by gravity to the receiving container situated below. During the unloading of material ‘discharge cycle’ a reverse jet compressed air blast cleans the filter in the lid of the hopper. An option is available to use a bag shaker mechanism in place of the reverse jet air blast. At the end of the discharge cycle the system automatically resets to continue on with the next convey cycle.

- The Uni-Vac Advantage

-

The Hanningfield Uni-Vac range of vacuum conveyors has been carefully designed and improved through 20 years of Hanningfield's experience with conveying. The Uni-Vac has been specifically designed with the needs of the end-user in mind.

The conveyor benefits from an ‘easy-clean’ design, which allows the system to be easily dismantled for cleaning without the need for tooling. In line with this, the conveyor boasts a ‘crevice-free’ design, which makes a thorough clean easier.

This not only improves hygiene, but also decreases operational downtime by enabling faster cleaning turnarounds. Furthermore, all units are constructed from either 304 or 316 stainless steel to suit your process.

Hanningfield’s knowledge in the application and manufacture of lift systems also enables them to provide tailored designs, whereby the vacuum system can be hoist-mounted for increased flexibility. Hanningfield can also offer static or mobile versions dependent upon your needs.

Importantly, Hanningfield are also able to remotely locate controls away from the vacuum conveyor itself. Not only does this comply with GMP, but it also offers a hygiene based advantage, because the unit becomes easier to maintain and clean.

Hanningfield's knowledge also helps them to solve problems and improve processes. For example, Hanningfield experience with vacuum conveying and size reduction makes Hanningfield experts at directly conveying into a cone mill, often known as ‘in-line cone milling’. This can significantly improve both the productivity and hygiene of a process. Hanningfield cross-discipline expertise makes Hanningfield unique in their ability to understand and solve customer problems.

With a wealth of knowledge, Hanningfield are proud to be an expert in the design, manufacture and maintenance of vacuum transfer solutions. Hanningfield have manufactured vacuum conveying systems for many companies around the world, their experience and understanding of vacuum conveying make them confident they could help to solve your problem too.

The Uni-Vac offers an excellent return on investment and has many advantages, including:

Improved productivity:

- Increases throughput and efficiency compared with manual handling

- Reduces loss of material

- Minimal risk of contamination

- Easy to clean design for minimal operational downtimeImproved working environment:

- Reduces air-born dust

- Increased safety and hygiene through automation of pick-up and transfer

- Reduced operator fatigueHigh return on investment:

- Increased productivity, allowing more material to be processed

- Less product loss, resulting in improved efficiency

- Minimal risk of contamination, reducing number of condemned batches - Find Your Vacuum Conveying Solution

-

Hanningfield have over 20 years experience with vacuum conveying. Hanningfield currently manufactures 6 different sizes of Uni-Vac Vacuum Conveyor System, ranging from a capacity of 3 to 100 litres, and a throughput of 300-4000 kgs/hr.

Each size caters for a different requirement, dependent upon your application. If you are at all unsure or require any help, please do not hesitate to contact us and a technical engineer will be able to assist you.

To browse each solution, simply select a size from the Uni-Vac list below:

V-03 Model The capacity is 3 litres and the throughput can reach 300 kgs/hr. More info

V-10 Model The capacity is 10 litres and the throughput can reach 900 kgs/hr. More info

V-20 Model The capacity is 20 litres and the throughput can reach 1200 kgs/hr. More info

V-30 Model The capacity is 30 litres and the throughput can reach 2000 kgs/hr. More info

V-50 Model The capacity is 50 litres and the throughput can reach 3000 kgs/hr. More info

V-100 Model The capacity is 100 litres and the throughput can reach 4000 kgs/hr. More info

- Gallery

- See it in Action!

-

Attention please. This is a large file and may take time on slow connections to load.

Click to download in FLV format (19.86MB)

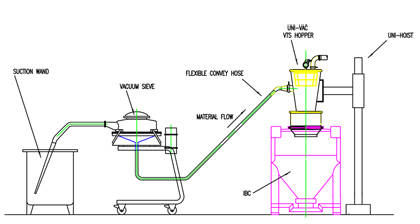

IBC Loading using Vacuum Transfer

Vacuum transfer into an IBC offers a reliable dust-tight transfer that is highly flexible and easily adapted to various process changes. Using vacuum transfer is an ideal material handling solution where there is restricted space above the IBC. Even in tight spaces, loading rates of 1,000 kg per hour are often possible.

"Vacuum transfer is a simple, fully-contained method for loading an IBC"

To ensure the best possible powder transfer from the vacuum transfer hopper into the IBC, a dust-tight seal is essential. This can take the form of a dust cap, flexible silicone sleeve, inflatable sealing system or a split butterfly docking system, to give the highest level of integrity. It is worth remembering that it is essential to vent the IBC or receiving container, in order r to disperse displaced air during filling. This is easily done using a vent filter. Vent filters can be simple fabric sock-type filters or miniature HEPA filters.

Material pick-up can be achieved in a variety of ways. The most common method is of material pick-up is using a hand held vacuum wand. To minimise any dust concerns during this process a localised dust extract system can be used. Alternatively a Sack-Tip Station or feed bin provides a semi-automated method of material pick-up. These systems can incorporate a dust-hood and integrated or external dust extraction to further help improve containment. Finally, powder can be drawn straight from the outlet of one IBC and transferred to another.

One major advantage is that other processes such as sieving or milling can be performed 'in-line'. This helps reduce operator exposure and eliminates the need for a separate process step providing a major cost benefit. From pick-up point to discharge a fully contained system helps protect both the environment and personnel from the hazards of airborne dust particles.

Using vacuum transfer, processes such as milling and sieving can be performed ‘in-line’

Improved containment using vacuum transfer for IBC loading also means reduced waste which further contributes to overall cost savings. Taking into consideration the benefits of flexibility, containment, labour savings and ease of cleaning, vacuum transfer for the loading of IBC’s and other bulk containers is the normally the optimal solution.

Pharmaceutical Powder Loading

The loading of machines with powder can be a complicated and troublesome process.

The biggest issue is nearly always containment. How do you ensure that no powder is leaked or lost during the transfer?

A common problem occurs during the loading of tablet presses, granulators, high-shear mixer, capsule filling machines etc. Often these are loaded from IBCs in the room above the process room. The difficult part is ensuring the powder transfers from the IBC to the machine without any mishaps. There are a number of ways to achieve a solution including utilising a rotary valve for controlling the flow of powder, or an interlock system between feed chute and IBC outlet.

A common problem occurs during the loading of tablet presses, granulators, high-shear mixer, capsule filling machines etc. Often these are loaded from IBCs in the room above the process room. The difficult part is ensuring the powder transfers from the IBC to the machine without any mishaps. There are a number of ways to achieve a solution including utilising a rotary valve for controlling the flow of powder, or an interlock system between feed chute and IBC outlet.

An alternative problem maybe loading a machine that is on the same floor as the IBC. How do you transfer the powder from the IBC, into the machine, without spilling or losing powder? In this scenario vacuum transfer is an excellent method of overcoming this problem.

Hanningfield have more than 20 years experience in pharmaceutical processing and have helped numerous manufacturers to solve this problem. All our equipment is manufactured by ourselves in the United Kingdom. Although each application is different, each objective is the same - to load powder into the machine without any issues.

For more information on how to solve this problem, please just contact us.

Milling & Conveying

The following video shows the simultaneous application of Hanningfield 'Uni-Mill' and 'Uni-Vac' machines in milling material and transfering the output powder from point A to point B in a fast and efficient way:

Download Brochure:

![]() Vacuum Conveying Systems (Uni-Vac Series)

Vacuum Conveying Systems (Uni-Vac Series)

Unknown

Unknown Unknown

Unknown Mozilla

Mozilla